This product has been discontinued and removed from our shelves.

The SF-EW180 single facer is commonly employed in producing the corrugated cardboard having thin flute profiles, like cell phone boxes, artware boxes, etc. Big flute sizes are also available here. The assembling of this product can be done on the basis of required speed and flute sizes. The location of this machine in the WJ computer high speed corrugated cardboard production line is displayed in diagram ③ and that in the HS high speed corrugated cardboard single sheet production line is presented in drawing ③.

Features

1. The design speed of the single facer is either 120m/min or 180m/min.

2. The effective breadth of the product is between 1400mm and 2200mm.

3. The flute size is A, B, C, E, F or G for customers to choose.

4. The corrugating rollers have two kinds of diameter designs, one beingΦ280 (design speed 120m/min), as well as the other being Φ320 (design speed 180m/min) and Φ360 (design speed 220m/min). They utilize 48CrMo alloy steel. After the heat treatment, the surface hardness reaches HRC55-58. In addition, the surface is plated with hard chrome, and grinded.

5. The product takes advantage of domestically advanced inner suction technique, and corrugating rollers with ring-shaped crescent slots. This ensures low energy consumption, good air suction effect, excellent corrugating profile and high flute intensity. The single sided cardboard has a flat and exquisite appearance without ring-shaped scales which may be caused by cover absorption type or leading claw type single facer.

6. This machine is easy and convenient for operation.

7. The glue coating section is designed separate from the whole product. Thus, it can be moved out completely for convenient repair and maintenance.

8. The equipment chooses intrusive glue coating method with the gluing width and glue quantity being electrically and manually adjusted, respectively. Moreover, the gluing gap supports manual or electrical adjustment.

9. When the glue quantity is under the control of the electrical system, the gluing gap is digitally displayed. Optionally, it also supports automatic tracking adjustment in accordance with the speed of the whole production line.

10. The driving section is seperated from the whole equipment, and has an independent drive box. The universal joint works for transmission. As a result, the whole single facer is able to run steadily at a high speed.

11. This product can be selectively matched with a spraying unit to modulate moisture content of corrugated medium.

12. The main drive uses the variable frequency motor which is managed by the PLC to keep pace with the whole production line.

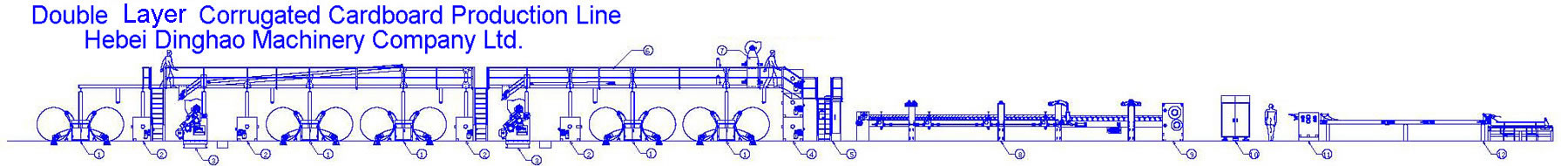

Structure Drawing of WJ Computer High Speed Corrugated Cardboard Production Line

1. Mill Roll Stand

2. Corrugated Cardboard Preheater

3. Single Facer

4. Corrugated Cardboard Glue Coating Machine

5. Escalator

6. Corrugated Cardboard Conveyor

7. Rectification and Tension Machine

8. Drying and Shaping System

9. Main Driving System

10. Corrugated Cardboard Slitter Scorer

11. Corrugated Cardboard Cutting Machine

12. Stacker

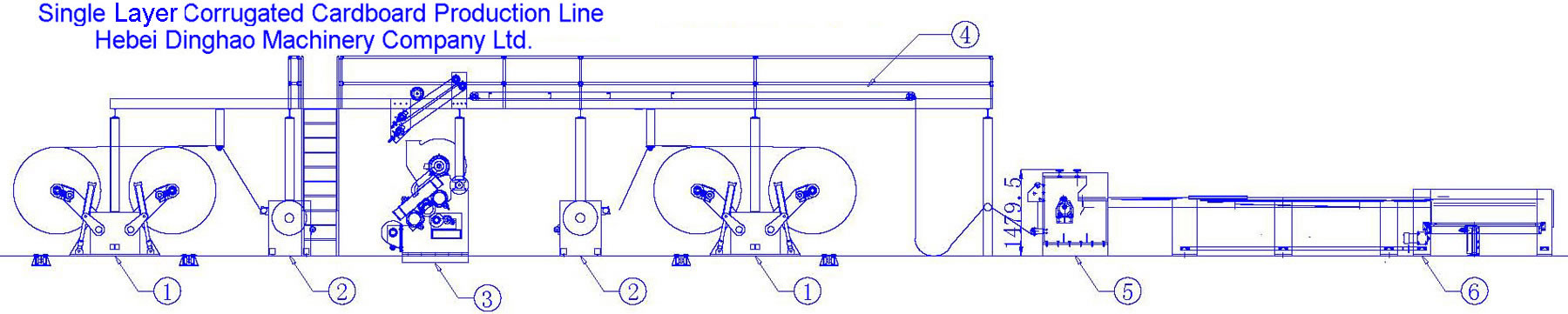

Structural Drawing of HS High Speed Corrugated Cardboard Single Sheet Production Line

1. Mill Roll Stand

2. Corrugated Cardboard Preheater

3. Single Facer

4. Feeding Overbridge Conveyor

5. Stacking Machine