This product has been discontinued and removed from our shelves.

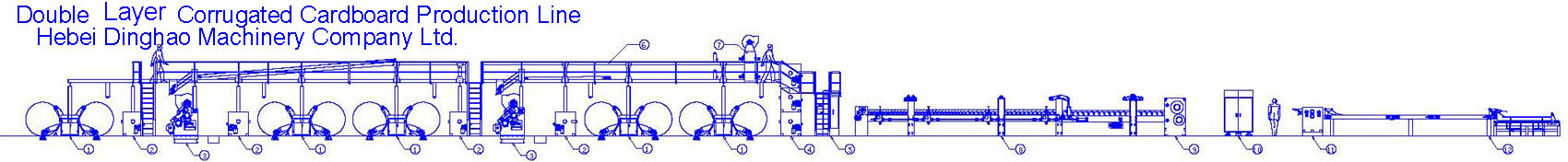

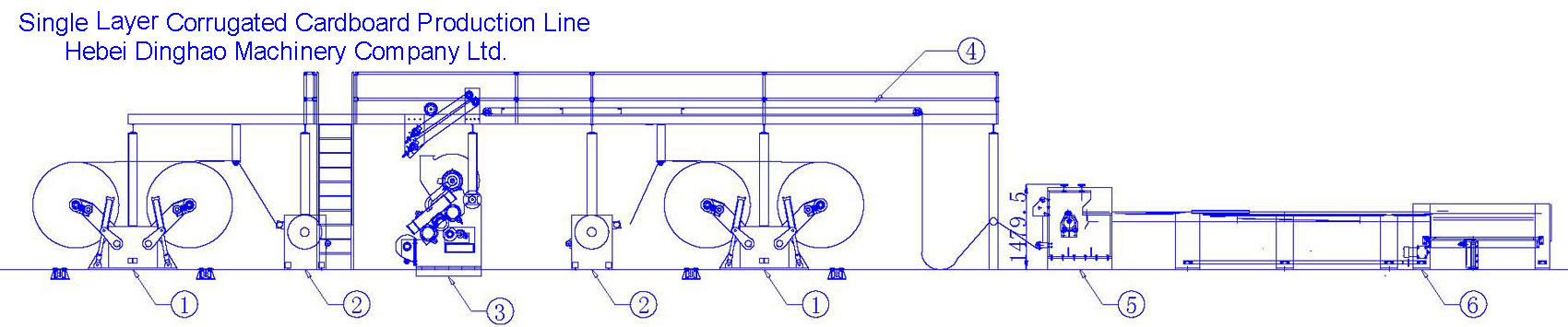

The location of the fully-auto hanging-basket stacking machine in the WJ computer high speed corrugated cardboard production line is represented in the diagram (12) and that in the HS high speed corrugated cardboard single sheet production line is illustrated in the drawing ⑥.

Technical Specifications

1. Max. Cardboard Stacking Height: 1500mm (The stacking height should be over 3 times greater than the cardboard width)

2. Max. Stacking Length: 3000mm

3. Min. Stacking Length: 500mm

4. Max. Stacking Weight: 3.0t

5. Pressure of Compressed Air System: 0.4-0.6MPa

Features

1. The fully auto hanging basket stacking machine has the functions of conveying and stacking cardboards.

2. Its conveying part is divided into 5 segments. The first and second ones adopt vacuum absorption and narrow conveying belt. They have the paper pressing board for delivering paper in a flat way. The third, fourth and fifth ones employ the wide conveying belt which can prevent deviation. At the paper outlet there is a pneumatic sun wheel press roller, as well as left and right paper blocking boards for orderly cardboard output.

3. The conveying belt of each operation segment is controlled by computer in terms of operation speed, counting, heap separating and stacking height.

4. The lifting motor of the stacking machine elevates the paper splicing roller plate for paper splicing. The roller plate falls down according to the stacking speed of the cardboard. As it is filled with the cardboard or the cardboard reaches a given position, the roller plate will fall down at a fast speed. As the height of the roller plate is the same as that of the conveying vehicle, the stacked cardboard will be automatically delivered onto the conveying vehicle. When the paper splicing roller plate falls down at a fast speed, the cardboard located at conveying part can not move forwards. Then, the roller plate will be quickly lifted to the highest position for continuous paper conveying.

5. The cardboard on the conveying vehicle will be moved with the manual hydraulic trailer.

6. The stacking machine is attached with 2 paper splicing roller working platforms whose total length is 6m.

7. It is equipped with a colorful touch screen as a standard for supervision of the field operation.

8. The product, working automatically, boosts high efficiency and reduces labor intensity of operators.

Structure Drawing of WJ Computer High Speed Corrugated Cardboard Production Line

1. Mill Roll Stand

2. Corrugated Cardboard Preheater

3. Single Facer

4. Corrugated Cardboard Glue Coating Machine

5. Escalator

6. Corrugated Cardboard Conveyor

7. Rectification and Tension Machine

8. Drying and Shaping System

9. Main Driving System

10. Corrugated Cardboard Slitter Scorer

11. Corrugated Cardboard Cutting Machine

12. Stacker

Structure Drawing

1. Paper Mill Roll Stand

2. Corrugated Cardboard Preheater

3. Single Facer

4. Feeding Overbridge Conveyor

5. Stacking Machine